Reel-in-a-Box Flat Drop Cable

- Description

- Additional information

- Properties

- Data Sheets

Description

Reel-in-a-Box Flat Drop Cable

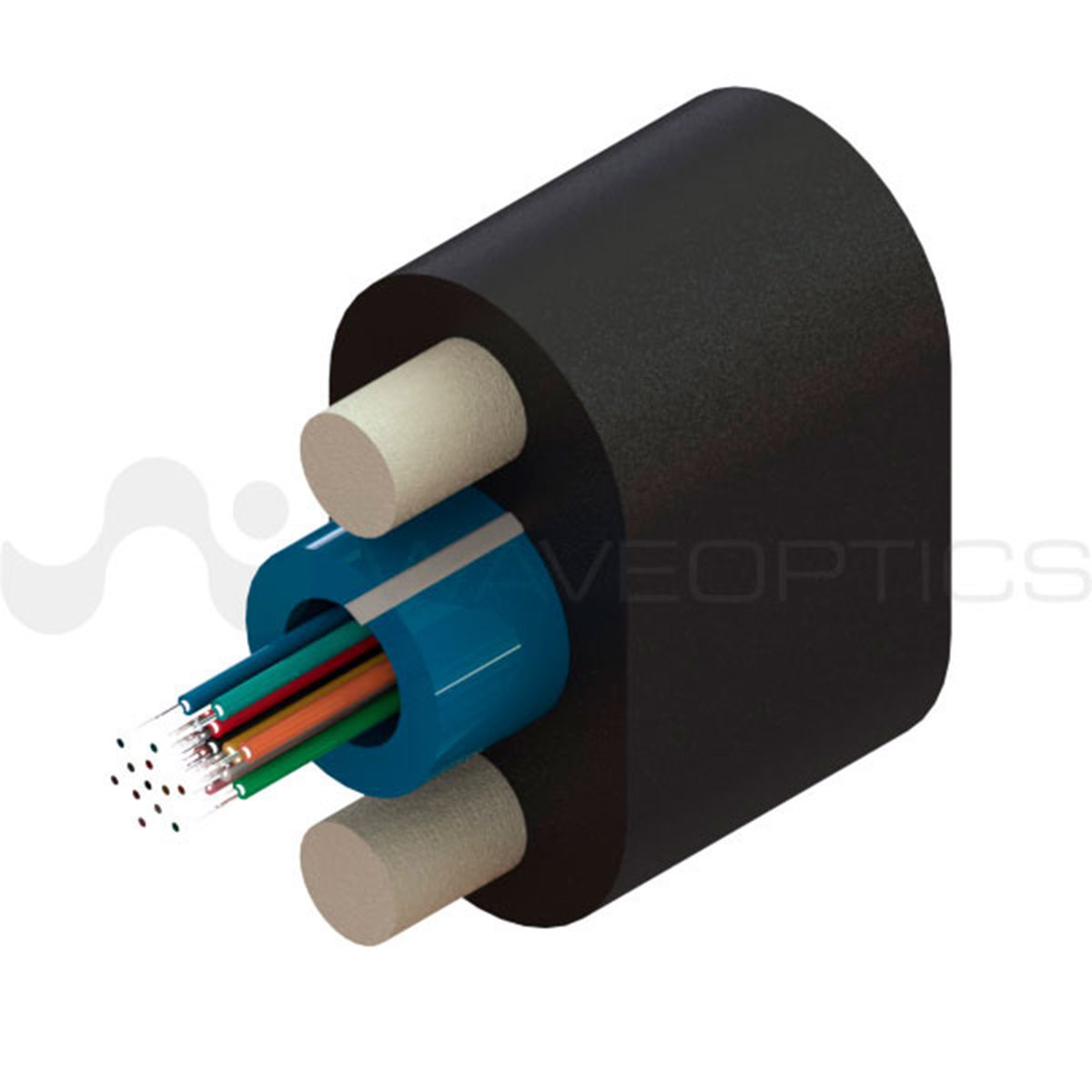

Waveoptics® Flat Drop Cable is designed for self-supporting, direct-buried and duct installations. Fully dielectric design, ideal for drop applications, offering ease of access as well as easy installation.

Single loose tube made of PBT which provides great mechanical properties under a wide range of conditions such as crush test and impact test. PE single jacket with additives makes a resistant, durable and easy to strip cable, providing superior protection against UV radiation, fungus, abrasion and other environmental factors.

Two parallel dielectric strength members that require no bonding or grounding, offering exceptional crush resistance. The FRP strength members are coated with EAA for improved adherence.

Reel-in-a-box packaging makes a quicker and easier installation, providing a cost-friendly and time-efficient installation method.

Additional information

| Fiber Count | 1 Fiber, 2 Fibers, 4 Fibers, 6 Fibers, 8 Fibers, 12 Fibers |

|---|---|

| Fiber Type | Waveoptics G652.D, Waveoptics G657.A1, Waveoptics G657.A2, OFS G652.D, OFS AllWave® FLEX |

| LT Water Protection | Dry, Gel-Filled |

Design Properties

| Fiber per Tube | 1-12 |

| Nominal Outer Dimensions | 8.0 mm x 4.5 mm (0.32 in x 0.18 in) (±5%) |

| Dielectric Strength Member Material / Diameter | EAA Coated FRP / 1.65 mm (0.06 in) |

| Outer Jacket Material | Polyethylene |

| Loose Tube Diameter | 3.0 mm (0.12 in) |

| Drum Length | 2,000 ft (±5%) |

Temperature Range

| Operation | -40°C to 70°C (-40°F to 158°F) |

| Installation | -30°C to 70°C (-22°F to 158°F) |

| Storage / Transport | -40°C to 70°C (-40°F to 158°F) |

Mechanical Properties

| Crush Resistance (Short-Term / Long-Term) | 2,200 N/100mm / 1,100 N/100mm |

| Minimum Bend Radius (Operation / Installation) | 10 x OD / 20 x OD |