Air Blown Micro Cable Gel-Filled

- Description

- Additional information

- Properties

- Data Sheets

Description

Air Blown Micro Cable Gel-Filled

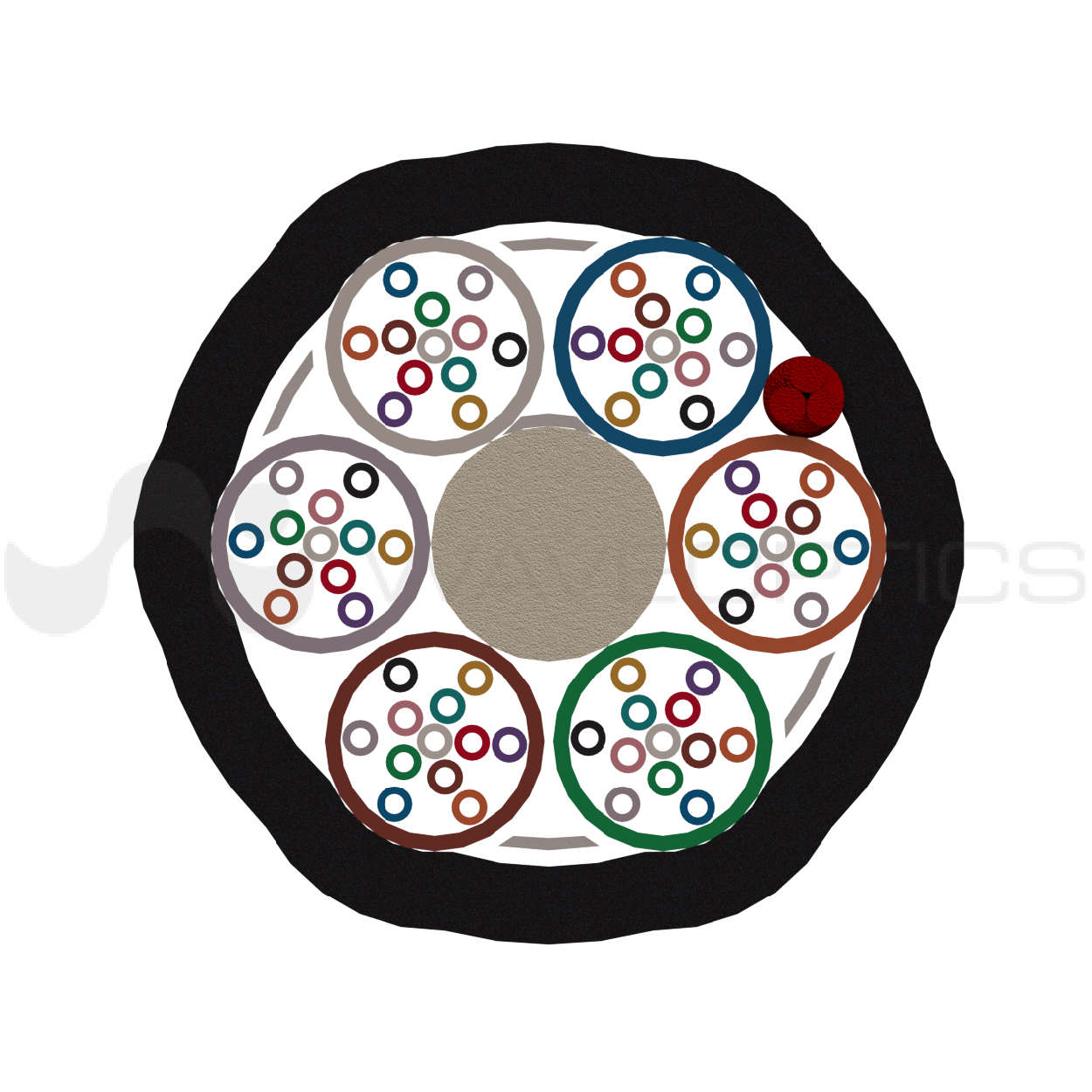

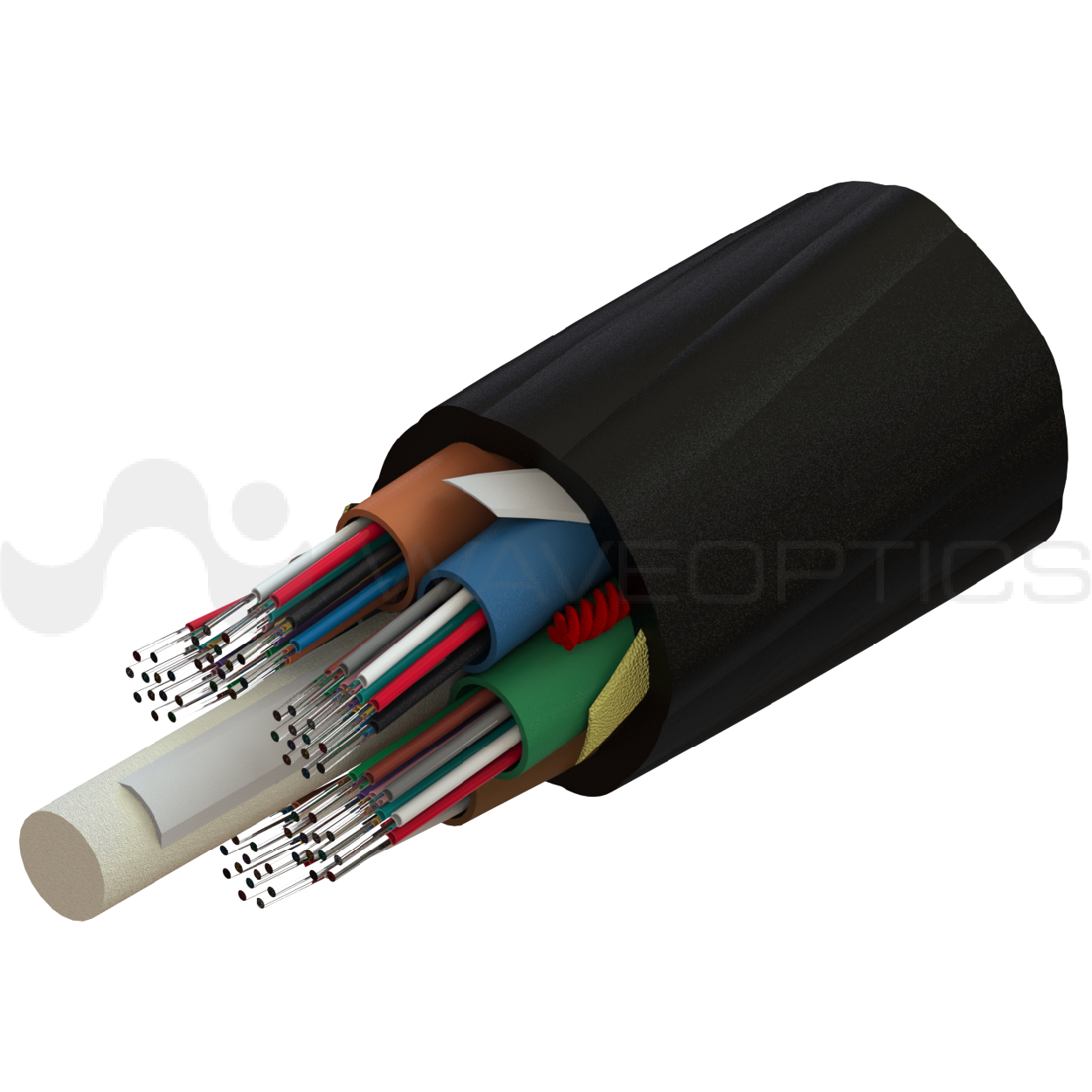

Waveoptics® Air Blown Micro Cable Gel-Filled all-dielectric design with a small outer diameter, makes it ideal for microduct applications, lowering deployment cost, allowing the usage of the air blown fiber method for installation. Designed for microducts with an inner diameter ranging from 8 mm to 16 mm, according to the fiber count.

Loose tubes are made of PBT which provide great mechanical properties under a wide range of conditions and are filled with water blocking gel.

PE single jacket with additives makes a resistant, durable and easy to strip cable, providing superior protection against UV radiation, fungus, abrasion and other environmental factors.

The SZ-stranded method for loose tube sand one ripcord ensure a quick and easy mid-span access.

Dielectric central strength member requires no bonding or grounding.

Internal and external water blocking yarn sand water blocking aramid yarn used as binder, providing protection against water penetration and adding tensile strength.

Additional information

| Fiber Count | 12 Fibers, 24 Fibers, 36 Fibers, 48 Fibers, 72 Fibers, 96 Fibers, 144 Fibers, 192 Fibers, 216 Fibers, 288 Fibers |

|---|---|

| Cable Length | 10,000 ft |

| Fiber Type | Waveoptics G652.D, Waveoptics G657.A1 |

Design Properties

| Fiber per Tube | 12-88 |

| Dielectric Strength Member | FRP |

| Outer Jacket Material / Thickness | Polyethylene / 0.5 mm (0.02 in) |

| Loose Tube Material / Diameter | 12-144 Fibers: 1.4 mm (0.06 in) 192 – 288 Fibers: 1.7 mm (0.07 in) |

| Drum Length | 10,000 ft (±5%) |

Temperature Range

| Operation | -40°C to 70°C (-40°F to 158°F) |

| Installation | -30°C to 60°C (-14°F to 140°F) |

| Storage / Transport | -40°C to 70°C (-40°F to 158°F) |

Mechanical Properties

| Crush Resistance (Short-Term) | 500 N/100mm / 200 N/100 mm |

| Minimum Bend Radius (Operation / Installation) | 10 x OD / 20 x OD |

Data Sheets