Pushable Cable

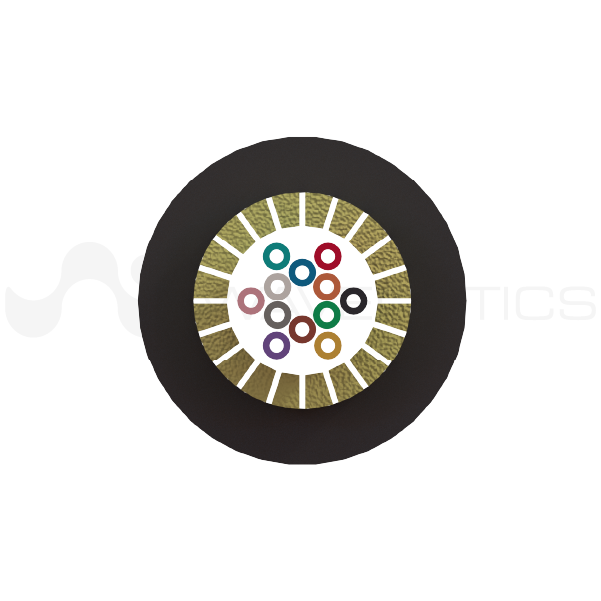

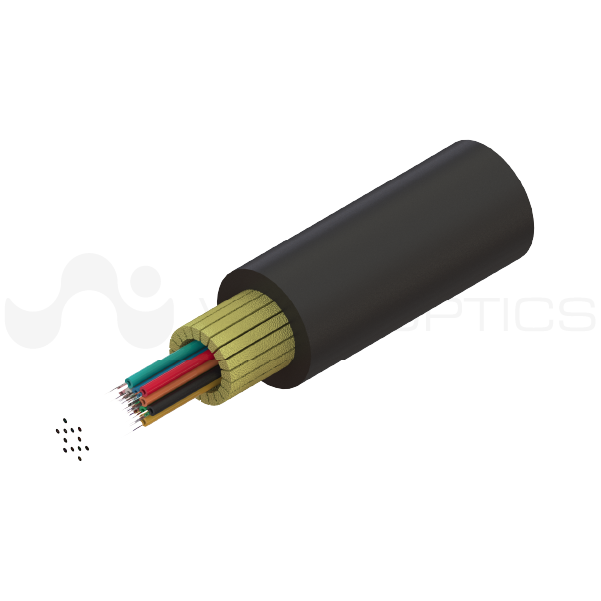

Waveoptics® Pushable Cable Gel-Filled is designed for installation in microducts. Outer jacket made of PBT which provides great mechanical properties under a wide range of conditions such as crush test and impact test. Aramid yarn is used as a strength member. These two elements combined make a light weight, robust and crush resistant cable that allows it to be pulled and pushed into a microduct, reducing fiber deployment cost, while maximizing the pulling and pushing distance.

- Description

- Additional information

- Properties

- Data Sheets

Description

Pushable Cable

Waveoptics® Pushable Cable Gel-Filled is designed for installation in microducts. Outer jacket made of PBT which provides great mechanical properties under a wide range of conditions such as crush test and impact test. Aramid yarn is used as a strength member. These two elements combined make a light weight, robust and crush resistant cable that allows it to be pulled and pushed into a microduct, reducing fiber deployment cost, while maximizing the pulling and pushing distance.

1 – 4 fibers configuration uses water blocking aramid yarn and 6 – 12 fibers configuration is filled with water blocking gel.

Additional information

| Fiber Count | 1 Fiber, 2 Fibers, 4 Fibers, 6 Fibers, 8 Fibers, 12 Fibers |

|---|---|

| Fiber Type | Waveoptics G657.A1, OFS AllWave® FLEX |

Design Properties

| Fibers per Tube | 1 – 12 |

| Nominal Outer Diameter | 2.95 mm (0.12 in) (±5%) |

| Dielectric Strength Member | Water Blocking Aramid Yarn |

| Outer Jacket Material / Thickness | PBT / 0.60 mm (0.0118 in) (±5%) |

| Drum Length | 3,200 ft or 10,000 ft (±5%) |

Temperature Range

| Operation | -40°C to 70°C (-40°F to 158°F) |

| Installation | -30°C to 60°C (-22°F to 140°F) |

| Storage / Transport | -40°C to 70°C (-40°F to 158°F) |

Mechanical Properties

| Maximum Crush Resistance | 500 N/100mm |

| Minimum Bend Radius | 50 mm (1.97 in) |

Data Sheets