Toneable Micro Flat Drop Cable

for drop applications, offering ease of access as well as easy installation. Compact and robust design provides ease of

handling and also reduces transportation and storage costs. Available in 250 micron bare (1 to 2 fibers) and 900

(01 fiber) micron tight-buffered (1 fiber) configurations.

- Description

- Additional information

- Properties

- Data Sheets

Description

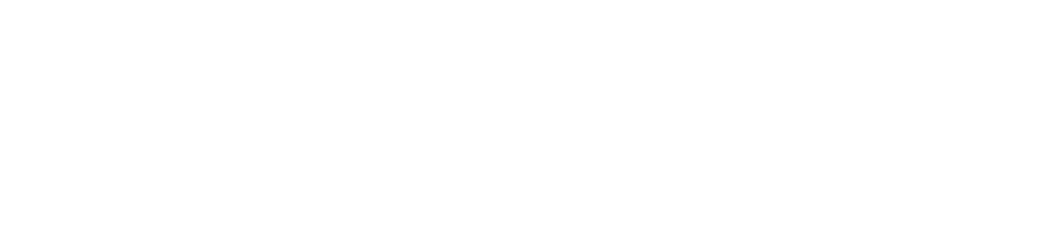

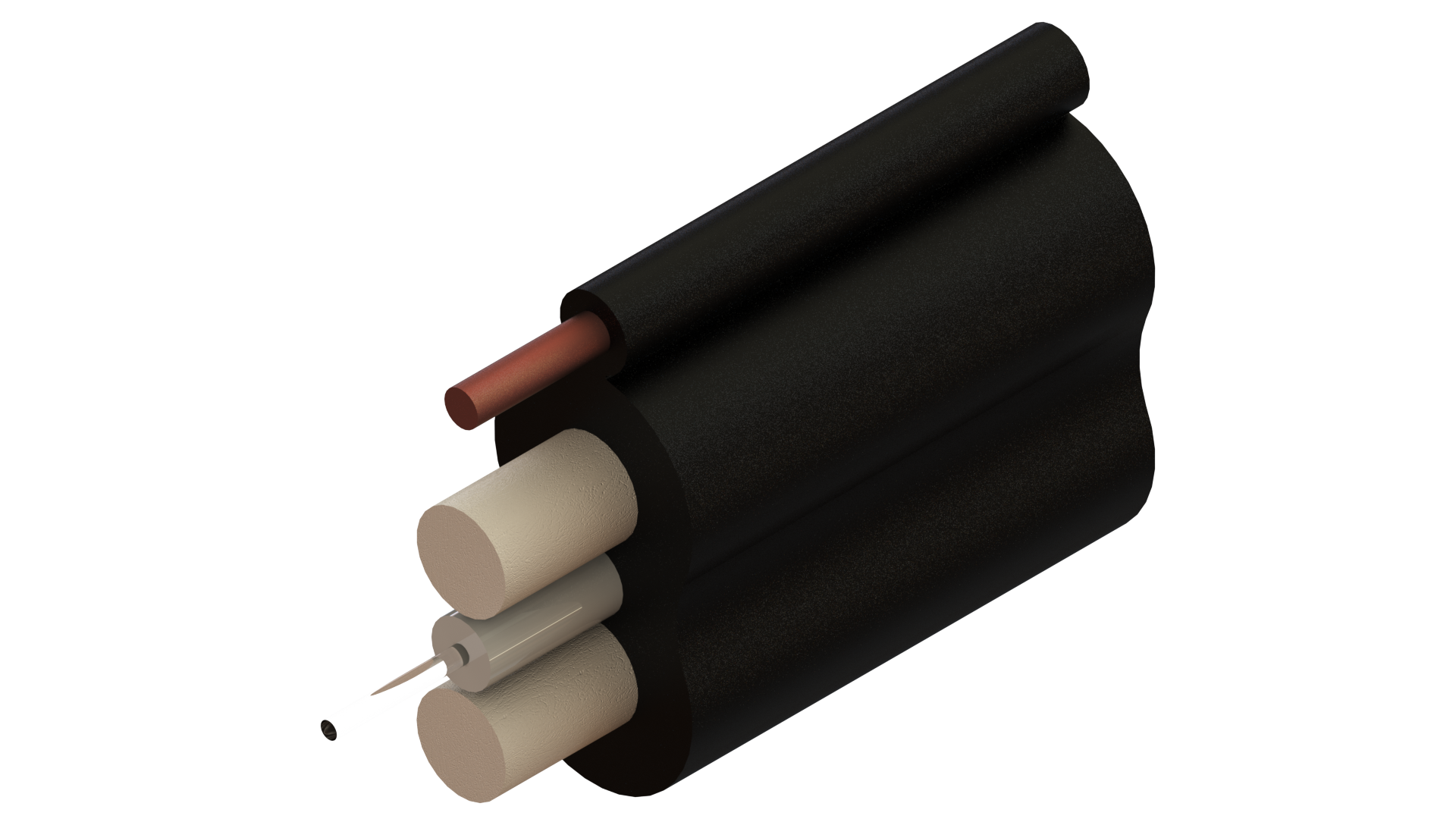

Toneable Micro Flat Drop Cable

Waveoptics® Toneable Micro Flat Drop Cable is designed for self-supporting, direct-buried and duct installations. Ideal for drop applications, offering ease of access as well as easy installation. Compact and robust design provides ease of handling and also reduces transportation and storage costs. Available in 250 micron bare (1 to 2 fibers) and 900 (01 fiber) micron tight-buffered (1 fiber) configurations. PE single jacket with additives makes a resistant, durable and easy to strip cable, providing superior protection against UV radiation, fungus, abrasion and other environmental factors. Two parallel dielectric strength members that offer exceptional crush resistance. The FRP strength members are coated with EAA for improved adherence. Copper toning conductor allows effortless detection in direct-buried installation.

Additional information

| Fiber Count | 1 Fiber, 2 Fibers, 4 Fibers |

|---|---|

| Fiber Type | Waveoptics G657.A1, Waveoptics G657.A2, Waveoptics G657.B3 |

| Cable Length | 2,500 ft, 5,000 ft, 10,000 ft, 20,000 ft |

Design Properties

| Fiber Count | 1-2 |

| Dielectric Strength Member Material / DIameter |

EAA Coated FRP / 1.35 mm |

| Toning Conductor | 24 AWG Copper Wire |

| Outer Jacket Material | LLDPE |

| Tight Buffer Material (900 um Configuration) |

LSZH |

| Drum Length | 5,000 ft, 10,000 ft & 20,000 ft (±5%) |

Temperature Range

| Operation | -40°C to 70°C (-40° F to 158° F) |

| Installation | -30°C to 70°C (-22° F to 158° F) |

| Storage / Transport | -40°C to 70°C (-40° F to 158° F) |

Mechanical Properties

| Crush Resistance (Short-Term / Long-Term) |

2,200 N/100 mm / 1,100 N/100 mm |

| Minimum Bend Radius (Operation / Installation) |

10 x OD / 20 x OD |

Data Sheets